Recycled Rubber

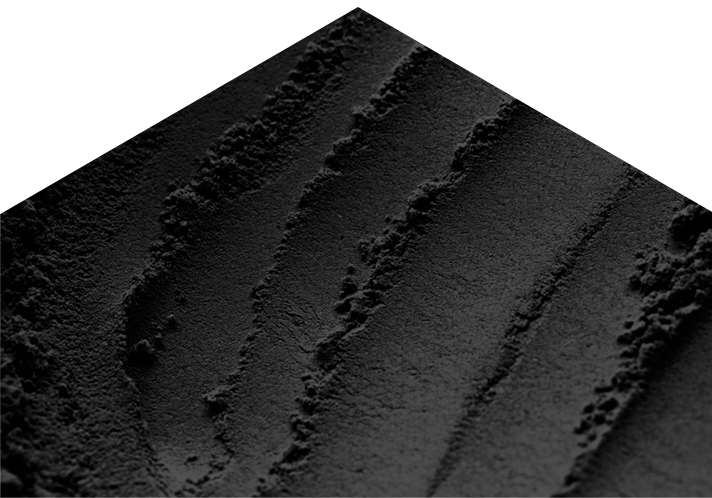

Recycled rubber is considered to be, for the most part, obtained from ground up discarded tires which are either left to be discarded or wasted. These tire crumbs can be produced in a variety of mesh sizes to accommodate uses in various applications. Sustaining the production of this kind of rubber eliminates the environmental risk and the build-up of waste in landfills. It can be manufactured at a low cost in comparison and with low energy requirements. Therefore, it is the most economical of all rubber options.

Most recently, industries using recycled products have sprouted a vast number of new applications such as rubber floorings, playground safety products, rubber mulch, shoes, highway safety barriers, speed bumps, and even molded recycled rubber sheets that compete with traditional vulcanized virgin sheet goods.

This has set the precedent to lead the production of less expensive and rather sustainable, yet durable products that benefit all aspects of the business including cost, community, consumers and the environment.

Reclaimed Rubber

Although Reclaimed rubber is similar to Recycled rubber, it would require a process involving de-vulcanization and re-vulcanization to create products similar to their petroleum based ancestors. Vulcanization involves the addition of the element of sulfur to the rubber itself which would alter it and create strong and sustainable bonds. These bonds are “cross-linked” and are responsible for strengthening the base material.

De-vulcanization involves the destruction of these bonds to extract the materials from the compound and therefore bring the rubber back to a more pliable state. The base material is vulcanized once more and then processed into sheets of rubber which are ideal for a wide variety of applications which rely on the use of any kinds of rubber.

Through this process, we are able to drastically extend the life of these rubber products allowing for a sustainable future we’re all seeking.

Recycled and Reclaimed Products

We’re proud to offer you green products that can be added to your formulas as replacements, fillers or process aids.

Butyl Reclaim

Butyl reclaimed rubber is produced when Butyl scrap rubber is put through a rigorous, multi-step production process. This includes sorting, crumbing, de-polymerization, refining, testing and packaging. Our manufacturers use this product in their formulas to reduce the amount of virgin material needed and to reduce their carbon footprint.

Whole Tire Reclaim

Whole Tire reclaimed rubber is produced when the entire rubber tire is put through a rigorous, multi-step production process. This includes sorting, crumbing, de-polymerization, refining, testing and packaging. Our manufacturers use this material in their formulas to reduce the amount of virgin material needed and to reduce their carbon footprint.

EPDM Reclaim

Due to its outstanding resistance to ozone and weathering, EPDM has been widely used the automotive and roofing industries. Reclaimed EPDM can be added to formulas to replace virgin material without changing it’s primary properties.

The EcoVadis sustainability assessment covers various aspects of sustainability, including environmental impact, labor and human rights, ethics, and sustainable procurement. Companies are evaluated based on their policies, actions, and results in these areas.

We are proud to have achieved a Gold rating this year from EcoVadis. This indicates that we’ve demonstrated a strong commitment to sustainability and performed well across a range of environmental, social, and ethical criteria. This Gold rating signifies our effectiveness in sustainability and a leadership in responsible business conduct.

Typically, when we think of “green” products, we only think of organically produced products that have grown from the ground, naturally. While this is true, the “green” label carries a meaning that is far deeper than that.

In fact, many recycled rubber products deserve the “green” label because they have longer life cycles, even if the raw materials don’t come from sustainable sources.

Contact Us

Please fill out the form and we will get back to you shortly.